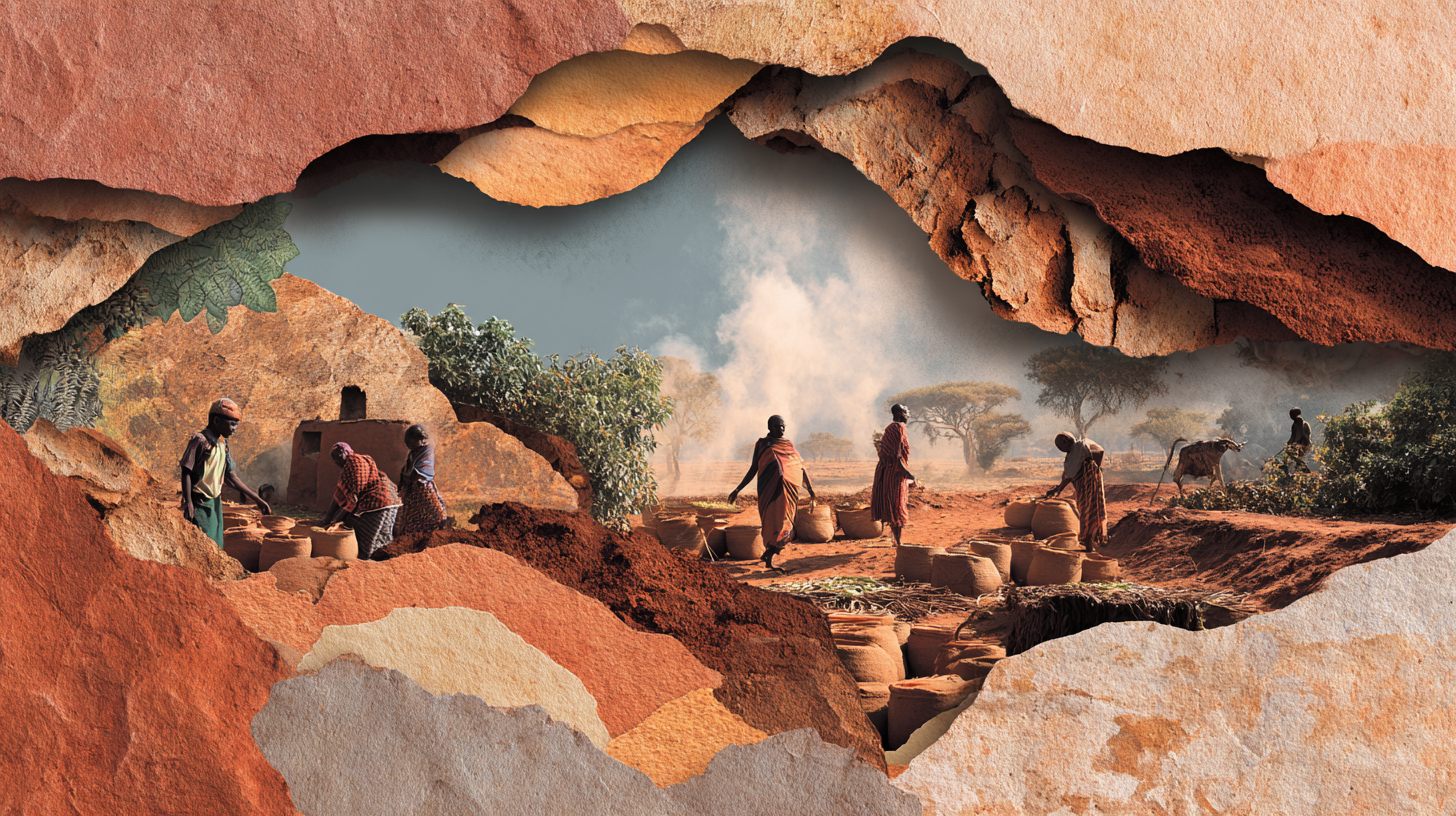

Every kiln we build is more than a piece of equipment — it’s a tool for healing land, empowering people, and restoring Africa’s natural balance.

African-Engineered Pyrolysis Systems — Precision Built for Performance and Permanence. Our kilns are not prototypes or lab concepts.

They are industrial-grade, field-proven pyrolysis systems designed, manufactured, and assembled entirely in Africa — capable of operating under real-world conditions to produce high-quality, carbon-credit–eligible biochar.

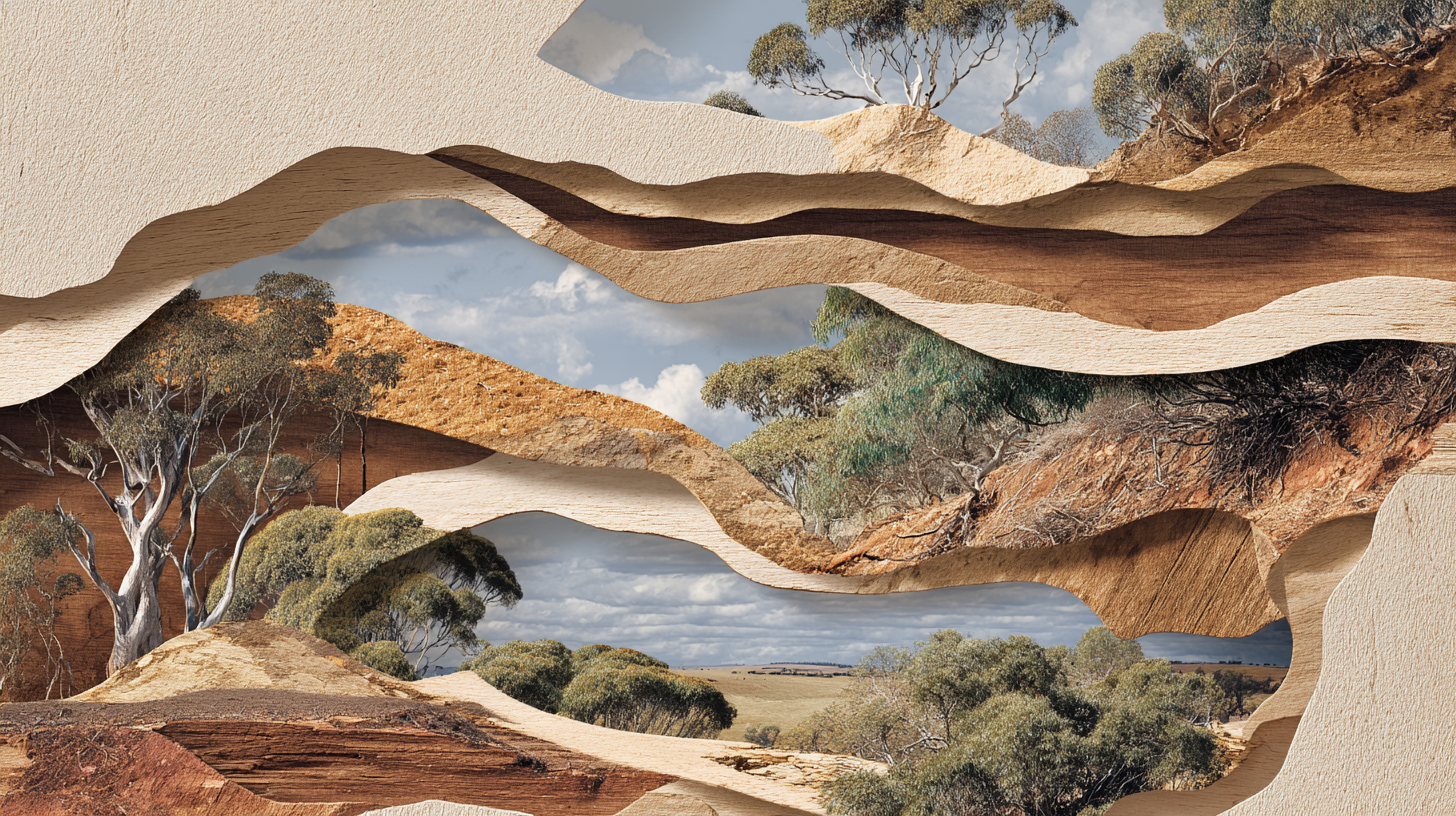

Built for African Feedstocks

Each kiln is designed to handle Africa’s diverse biomass — from dense hardwood invasives like mesquite, wattle, and blue gum, to lighter feedstocks such as wood chips, sawdust, and agricultural residues.

Because moisture, density, and volatile content vary widely, our systems are engineered for controlled, high-temperature pyrolysis to ensure consistent yields and carbon permanence.

WE MAKE 3 TYPES OF KILNS

Horizontal

Vertical

Combo (Horizontal + Vertical)

Each of them have with the following features:

Condenser system (to extract wood vinegar)

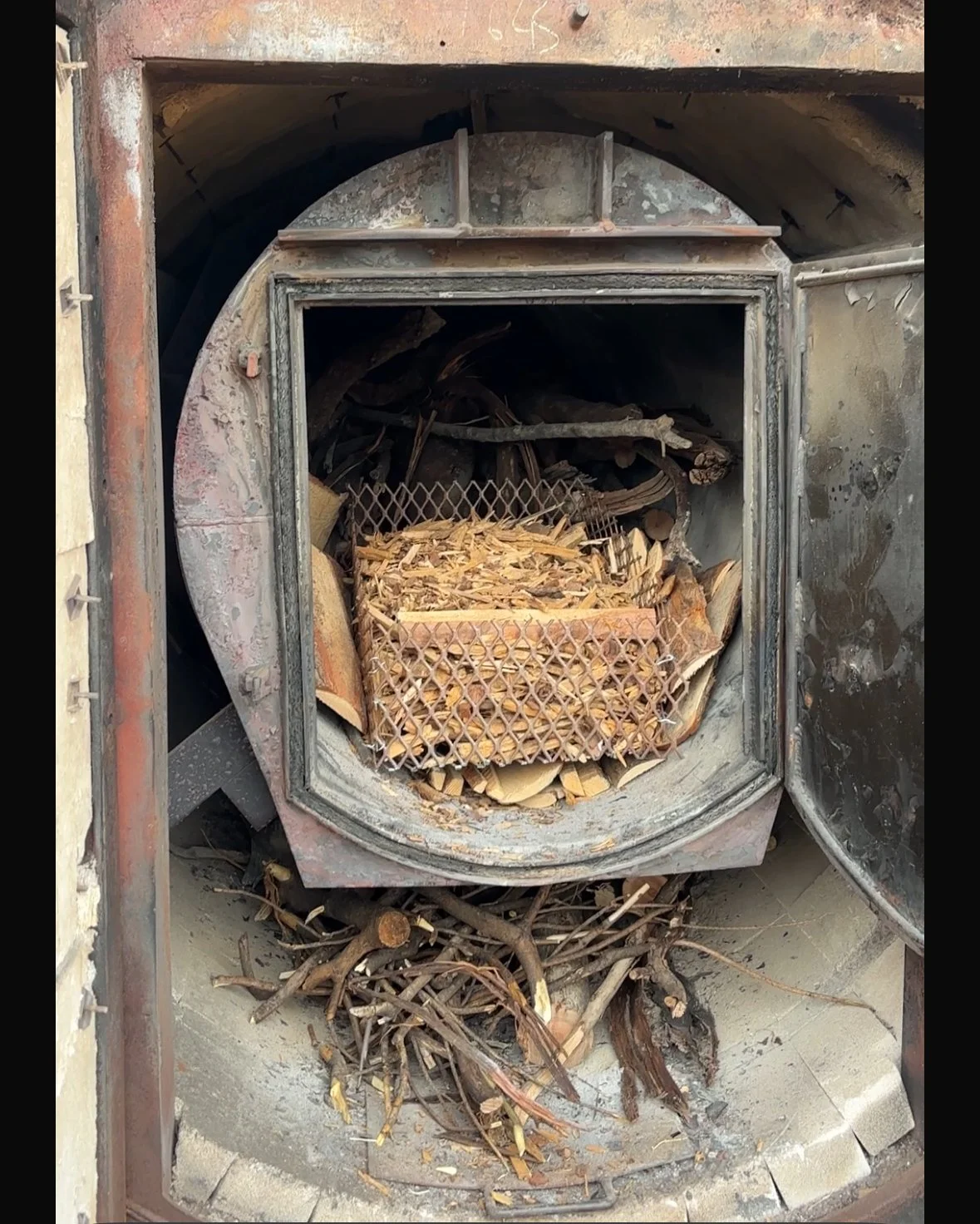

Built in fire box

Two temperature gauges

Thermocouples

Containers have two doors to access both sides

VERTICAL KILNS

Our vertical semi-batch kilns are designed for high-efficiency, small-to-medium scale biochar production. Fully insulated and built with durable stainless steel or boiler plate, they safely reach temperatures up to 750°C, converting a wide range of lightweight biomass—like wood chips, sawdust, rice husks, nut shells, and even agricultural residues—into valuable biochar and wood vinegar.

Each batch runs in about 3 to 4 hours, with the ability to process up to 32 cubic meters of material per day. The system also captures and recycles the syngas produced, making the process low-emission and energy-efficient.

Perfect for community use, agricultural hubs, or decentralized rural setups, these kilns support sustainable land management, soil regeneration, and circular economies.

Horizontal Kilns

Our horizontal batch kilns are designed to handle larger, denser feedstocks like tree stumps, logs, and woody biomass. These kilns are fully insulated with high-heat fire blankets and built using heavy-duty stainless steel or boiler plate to ensure durability under continuous high-temperature use—up to 750°C.

Available in single or double chamber options, they can process up to 26.4 cubic meters of material in 24 hours, making them ideal for larger-scale biochar production where bigger feedstocks are available.

Each batch runs between 5 to 8 hours, producing both biochar and wood vinegar, with all syngas byproducts captured, condensed, and re-burned for a cleaner, low-emission process.

These kilns are perfect for agroforestry systems, communal land clearing efforts, or forestry-based carbon projects where high-capacity processing and sustainability go hand in hand.

COMBO KILNS: HORIZONTAL & VERTICAL

Flexible. Efficient. Designed for Impact.

The TBC Combo Kiln brings together the best of both worlds—horizontal and vertical kilns—in one fully insulated, high-performance system. Built for communities and projects that require versatility across biomass types, this hybrid model allows you to process everything from dense woody logs to fine agricultural residues—all with low emissions and maximum yield.

Key Features:

Dual Chamber Design: Combines a 4.1m³ vertical unit and a 6.6m³ horizontal unit, giving you over 21m³ capacity every 24 hours.

Batch Times:

Vertical: 3–4 hours per cycle (for fine, dry feedstock)

Horizontal: 5–8 hours per cycle (for heavier woody biomass)

Materials: Durable Stainless Steel (Gr310) or Boiler Plate Steel, both wrapped in a 1400°C fire blanket for heat retention and safety.

Compatible Feedstock:

Woody biomass like logs, stumps, and branches

Light material like wood chips, sawdust, rice husks, nut shells, agricultural waste, even dry sewage

Outputs:

Biochar for long-term soil regeneration and carbon storage

Wood Vinegar for organic farming and microbial stimulation

Syngas: Recycled and combusted through a closed-loop condenser system for a cleaner burn.

This system is ideal for community hubs, agroforestry projects, or municipal waste-to-value initiatives where feedstock variety is high and daily output matters. It’s a resilient, adaptable solution to accelerate local livelihoods and carbon removal at scale.

FAQS

-

TBC kilns are designed to handle a wide range of feedstocks depending on the kiln type.

Our vertical kilns are best for light, fine, and fast-drying materials like wood chips, sawdust, rice husks, nut shells, agricultural waste, and even dry sewage.

Our horizontal kilns are ideal for bulkier, woody biomass like branches, tree stumps, and logs.

We prioritize invasive species and local biomass that would otherwise go to waste, turning it into a valuable carbon resource.

-

TBC kilns are fully insulated, locally adaptable, and designed with Africa’s diverse biomass in mind. We focus on:

High efficiency burn cycles (3–8 hours)

Modular design for community scalability

Recycled syngas systems to minimize emissions

Output of both biochar and wood vinegar, boosting soil health and farm inputs

Plus, all our tech aligns with carbon credit standards and sustainable farming practices.

-

Yes! TBC kilns and our broader biochar model are carbon credit compliant, and we work with partners to ensure projects are eligible for verified carbon standards. Our biochar locks carbon in soil for hundreds of years and can contribute to climate-positive livelihoods.

-

Biochar is a stable form of carbon that improves soil structure, retains nutrients, and stores carbon long-term.

Wood vinegar (a by-product of biomass condensation) is used in organic farming as a natural pesticide, soil enhancer, and microbial booster.

TBC kilns produce both as part of a closed-loop system.

-

It depends on the kiln size and type:

Vertical kiln – up to 3.5 tons per day depending on feedstock, every 24 hours with a fast cycle of 3–4 hours per batch.

Horizontal kiln – up to 4.5 tons per day depending on feedstock, with slightly longer 5–8 hour burn cycles.

Exact biochar yield varies based on moisture content and biomass type.

-

Absolutely. Our kilns are designed with local contexts in mind, built for low-tech operation, minimal emissions, and community training. TBC provides local onboarding, usage protocols, and ongoing support to ensure both safety and impact.

-

TBC offers on-the-ground training, community engagement, and technical support to ensure that our systems are adopted, not abandoned. We also help implement monitoring and reporting tools for regenerative agriculture and climate tracking.

The Process